Is Baking Soda An Electrolyte

Rust Removal with Electrolysis - a Detailed Illustrated Tutorial, page fifteen

2. Making a Simple Electrolytic Setup:

How To Brand Electrolyte, Choosing a Proper Place for Setup

(...Continued from Previous Page)

vi) How To Make Electrolyte

Making an electrolyte is every bit uncomplicated every bit dissolving saccharide in your loving cup of coffee! Only now you are dissolving either washing soda (or "soda ash") or baking soda (also "breadstuff soda" and "cooking soda") in water. And you do not accept to mensurate a precise corporeality of soda y'all utilise to make an electrically conductive solution - electrolyte.

Many professionals claim that washing soda is more useful for electrolytic cleaning than baking soda considering the washing soda is routinely used to remove oil, grease, and certain minerals. Thus, as well providing ions to form electrolyte, it too provides a secondary benefit in electrolytic derusting, every bit the rusted atomic number 26 object likely contains these minor contaminants. All that is true; nevertheless, the washing soda is a skin irritant.

From my experience with electrolysis, I found out that the baking soda electrolyte is as effective every bit the washing soda solution, provides satisfactory results, and harmless - it does not irritate the skin. And the pocket-size contaminants - oil, grease and minerals, can be easily washed off the iron antiquity with acetone (see details in the "Displacing Water from Iron Surface" section on page 29) anyway. In case you wish to use the washing soda and are too lazy to become to the supermarket or drugstore to get it, you can utilize blistering soda to make the washing soda at abode.

Since the baking soda (sodium bicarbonate or sodium hydrogen carbonate - 2NaHCO3) differs from the washing soda (sodium carbonate - Na2CO3) but by the presence of moisture and carbon dioxide (CO2) in it, you can easily get rid of these ii components. Just put some baking soda onto a frying pan or a cookie canvas, and broil it in the oven at a niggling over 300°F (149°C) for an hour. Blistering soda volition become washing soda afterwards the carbon dioxide and h2o molecules are stale off by estrus:

2NaHCO3 -> Na2CO3 + H20 + CO2

A Few Words About Table SALT:

Some enthusiasts utilize table salt to brand an electrolyte, and probably are not aware of the hazards associated with toxic chlorine gas and its immediate harmful effect to their health.

Practice Non apply TABLE Common salt in your electrolytic solution! The electrolytic solution made with the tabular array salt will generate CHLORINE GAS that can injure you, and speedily!

Practice Non apply TABLE Common salt in your electrolytic solution! The electrolytic solution made with the tabular array salt will generate CHLORINE GAS that can injure you, and speedily!

When table salt (sodium chloride - NaCl) is placed in h2o, the salt (a solid) dissolves into its component ions, according to the dissociation reaction:

NaCl(solid) → Na+(aqueous) + Cl−(aqueous)

Then when the electrolysis starts, a gaseous mixture of Chlorine (Cl2) and Oxygen (O2), begins to evolve bubbling off the anode. The chlorine will deliquesce back into the electrolyte at first, but every bit the electrolyte gets saturated with the chlorine, the bubbles will come out of solution and ascension up forth with the oxygen in the mist directly above the bath.

Notation: Special attending should exist given to those iron artifacts that have rusted in a salt-water surround! They should undergo as many soakings in h2o equally possible to leach all salt molecules out of the porous atomic number 26 surface.

At that place is another gamble that can be caused by the chlorine during electrolysis. The hydrogen gas is bubbling off the cathode during the procedure, and if the chlorine is combined with the hydrogen, it volition react violently making Muriatic acid - "Houston, we've got a problem!"

Use Washing or Baking Soda, NO Salt!

Other hazards are created when people try to speed up the procedure past calculation lye (caustic soda) and even drain cleaners into an electrolyte. Lye (sodium hydroxide) is a powerful base and is very harmful: it will immediately damage the skin on contact, and then appropriate protection must be used.

I would circumspection anyone against using lye and bleed cleaners (full of contaminants) in the electrolyte! It has been proven that no observable increase of the process speed is achieved by using lye or any other harmful "add-on". Is it actually worth of taking the risks associated with usage of the hazardous textile and disposal of caustic solution?

H2o Used in Electrolyte:

It is more often than not recommended that only distilled water (available at virtually supermarkets) or de-ionized water should exist used for making the electrolyte. The tap water may contain certain minerals or chemicals that could be deposited on iron objects or interfere with the process.

For instance, the tap water is suspected of contributing to the formation of carbonate precipitate - black coating, on the derusted fe objects (come across details in the "What Is the Black Coating and..." section on page 27). I use the tap water, and and then just have to put more efforts into cleaning the iron piece afterwards.

Amount Of Soda To Make Electrolyte:

Recommended by dissimilar sources, the ratio "soda-to-water" for making electrolyte ranges from "i table spoon of blistering soda per five gallons of h2o" to "one tablespoon of washing soda per one gallon of water". I use the latter ratio for my electrolysis projects.

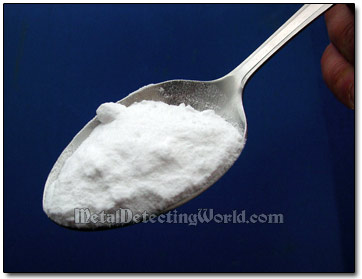

One Tabular array Spoon of Baking Soda per One Gallon of Water

If you lot employ a battery charger with an ammeter, in that location is a unproblematic way to determine an optimal amount of baking soda required for the amount of h2o in the container of any volume; no calculations and measurements are needed. After you place the electrodes and iron object into the container and connect everything (all details are covered in the following chapters), fill up the container with water (electrode connectors are not immersed!), set the amperage controlling knob in a middle position, turn on the bombardment charger, and slowly add a small amount of baking (or washing) soda into the container while stirring well, so all soda is speedily dissolved.

Now sentinel the ammeter indicator hand (or pointer) while adding more soda: the arrow will move slow at starting time, but and so will get faster, every bit the soda'south concentration in solution is increasing. When the pointer stops (amperage stops rising apace), the amount of soda in the solution is optimal, i.e. non too much current passes through the electrolyte to go the job done, so the power supply - your battery charger, will not be overloaded, and whatsoever connecting wires will not be burnt. Your electrolyte is ready! And your electrolysis machine can remove rust from your valuable atomic number 26 artifacts!

A Elementary Electrolytic Setup for Removing Rust

For How Long Can Electrolyte Be Used?

If it was non for the by-products and contaminants - any substances also baking or washing soda, that get into the electrolyte from water, anodes, cathodes, and atomic number 26 objects, and then gradually build up a huge disgusting mess in the container, one could use the electrolyte forever. I just would have to refill the container with water which is converted into oxygen and hydrogen gases during the process.

Just in reality this can be possible only if the platinum or graphite anodes are used. Otherwise, the grime, loosened rust and contaminants make the electrolyte unusable subsequently iv-6 hours, and, at this point, it is fourth dimension to change the electrolyte and precipitants (come across details in the "Crud and Precipitated Rust Disposal" section on page 41), and the electrolyte vat should be thoroughly cleaned.

Whatsoever residue of salt, grease, oil and clay should be cleaned off the IRON OBJECT beforehand in guild to avoid obvious contamination of the electrolyte. Failing to remove the contaminants will slower the process and shorten the life of the electrolytic solution.

7) Choosing a Proper Place for Setup

Because the electrolytic rust removal generates hydrogen gas, 1 has to brand sure the hydrogen gas and its mixture with oxygen - another by-production of electrolysis, do not accumulate to reach an explosive concentration. This is why the procedure must exist conducted in a very well ventilated area, and abroad from anything that can produce sparks or flames.

For your condom and prophylactic of your dwelling, your electrolytic de-rusting should be conducted outdoors! (all aspects of safety will be covered in the "Rubber Precautions" section on page xl) Every bit the battery charger normally is non designed for outdoors conditions, you should keep it indoors, and but run the connecting cables through a door to the electrolyte container placed outside your home.

Pelting and/or snowfall would not bear on the procedure unless rain or snowfall precipitation is heavy plenty to essentially dilute the solution. Freezing temperatures will not affect the electrolyte which volition remain warm during electrolysis. The place of your electrolytic setup should be adequately isolated from homo and creature traffic.

- < Previous

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- x

- eleven

- 12

- xiii

- 14

- 15

- 16

- 17

- 18

- nineteen

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- xxx

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- xl

- 41

- Next >

Is Baking Soda An Electrolyte,

Source: https://www.metaldetectingworld.com/make_electrolyte_p15.shtml

Posted by: tranagaven1966.blogspot.com

0 Response to "Is Baking Soda An Electrolyte"

Post a Comment